Among so many cable models, the fire resistance and flame retardant requirements are easily ignored by people, thus becoming a huge hidden danger of fire. Below, Zhengzhou Jinshui Industrial Co., Ltd. explains what aspects need to be considered when selecting the flame retardant grade of weak current cables.

The cable laying environment determines to a large extent the probability that the cable will be attacked by external fire sources and the possibility of prolonging the fire and causing a disaster.

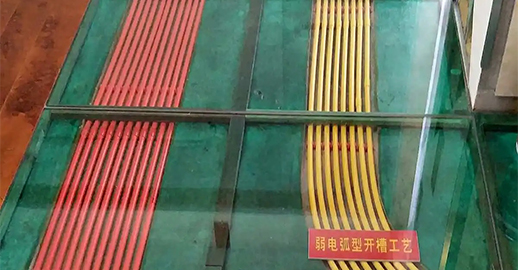

For example: non-flame-retardant cables can be used for directly buried or individually penetrated pipes (metal, asbestos, cement pipes), and placed in semi-closed bridges, cable troughs or special cable trenches (with covers), which can appropriately reduce the resistance. The flame retardant requirements are one to two. It is recommended to choose flame retardant class C or flame retardant class D.

Because there are less chances of being invaded by external factors in this environment, even if it catches fire due to the small space and occlusion, it is easy to self-extinguish and is less likely to cause a disaster.

On the contrary, the flame retardant level should be appropriately increased if the fire is exposed indoors, if the room is climbed through the building, or in a secret passage, mezzanine, or tunnel corridor, where human traces and fire are easily accessible and the space is relatively large and the air can easily circulate. It is recommended to choose flame retardant class B or even flame retardant class A.

When the above-mentioned environment is in front of or behind a high-temperature furnace or in a flammable and explosive chemical, petroleum, or mine environment, it must be handled strictly, and it is better to be high than low. It is recommended to use flame retardant Class A, or halogen-free low-smoke flame retardant and fire-resistant Class A.

The number of cables affects the flame retardant level of the cable. It is mainly the amount of non-metallic materials in the same space that determines the level of flame retardant. When calculating the volume of non-metallic materials of wires and cables, the concept of the same space refers to cables. A space where, in the event of a fire, its flames or heat can radiate unimpeded to nearby cables and ignite them.

For example, for trusses or trough boxes with fireproof boards that are isolated from each other, the same channel should refer to each bridge or trough box. If there is no fire isolation above, below or left and right, once a fire affects each other, it is appropriate to include them uniformly in the calculation of the non-metallic volume of the cables. .

After the volume of non-metallic cables in the same channel is determined, look at the outer diameter of the cables. If the cables are mostly small (diameter less than 20mm), the flame retardant category should be dealt with strictly. On the contrary, if the cables are mostly large (diameter 40mm or more), the flame retardant category should be treated more strictly. The reason for the low level is that cables with smaller outer diameters absorb less heat and are easy to ignite, while cables with larger outer diameters absorb more heat and are not suitable for ignition.

The key to forming a fire is to ignite it. If it is ignited but does not burn, the fire will extinguish itself. If it burns but does not extinguish, it will cause a disaster.

The flame retardant levels of wires and cables laid in the same channel should be consistent or similar. The extended flame of low-level or non-flame-retardant cables is an external fire source for high-level cables. At this time, even if A Class flame-retardant cables also have the potential to catch fire.

For cables used in major engineering projects, such as units above 30MW, ultra-tall buildings, banks and financial centers, large and extra-large crowded places, etc., the flame retardant level should be higher and stricter under the same conditions with other factors. It is recommended to choose Low-smoke, halogen-free, fire-resistant and flame-retardant cable.

Relatively speaking, power cables are easy to catch fire because they are hot and have the possibility of short-circuit breakdown. However, control cables and signal cables are in a cold state due to low voltage and small load, so they are not easy to catch fire. Therefore, it is recommended that , they are laid separately in the same space, with the power cables on top, and the control cables and signal cables on the bottom. Because the fire is upward, fire isolation measures are added in the middle to prevent burning objects from splashing.

Get A Free Quote

The number of cable cores is selected based on comprehensive consideration of multiple factors to ensure the rational use of the cable.

Copper core cables have excellent electrical conductivity, thermal conductivity and good mechanical strength.

Wires are an important part of circuit reconstruction. Household wires are mainly divided into copper wires and aluminum wires.

Submit Request

PDF Request