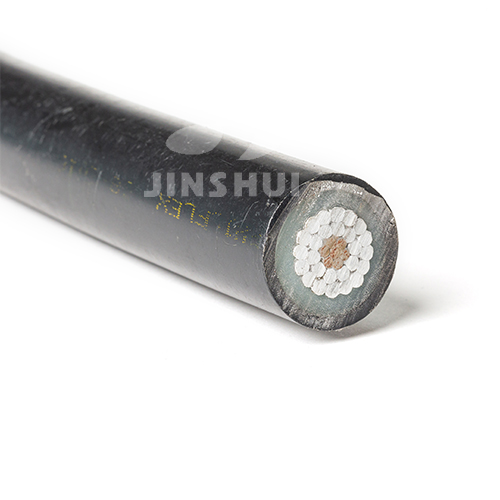

Aerial cable is a special cable manufactured using a production process similar to cross-linked cables. It is a new power transmission method between overhead wires and underground cables. Overhead cables are widely used in power transmission at home and abroad. Overhead insulated cables are generally high-voltage lines. Therefore, if they are underground or very close to a building, you must choose overhead insulated cables. Aerial cables are divided into single-core overhead lines, double-core overhead lines, three-core and other overhead insulated cables of various specifications.

In addition to meeting high electrical performance requirements, high-voltage overhead insulated cables also require good weather resistance to work safely under sunlight for a long time. It is beneficial to prevent typhoons. After using overhead insulated cable conductors, the instantaneous collision of the conductors will not cause a short circuit, reducing faults and greatly improving the line's ability to withstand typhoons.

The outer layer of the conductors of overhead insulated cables is covered with an insulating layer, which can effectively prevent the leakage of current, thus ensuring the safety and reliability of the conductors. When there are many overhead cables, the insulation layer can also reduce the distance between lines and increase the number of loops of lines erected on the same pole.

Because there is an insulating layer on the outside, it is less susceptible to oxidation and corrosion than bare wires and can resist oxidation and corrosion. It has strong corrosion resistance, so it can extend the service life of the line.

Because the outer insulation layer of overhead insulated cables has certain wear resistance and tensile resistance, it can effectively reduce the impact of external factors such as trees and dust, and reduce short circuits and grounding accidents. It will also reduce product maintenance costs.

It can be erected on any kind of pole tower or along the wall. Under special circumstances, it can also be walked through the trees and directly fixed on the tree pole with hardware. It can be set up as a single circuit or multiple circuits can be set up on the same pole.

Although the steel core is missing, its toughness allows the mechanical strength of the entire conductor to meet the stress design requirements. During installation and operation, overhead insulated conductors can withstand various mechanical forces, such as wind force, ice force, etc., thus ensuring the stability and safety of the power system.

1.Suitable for areas with more lightning. Since overhead insulated cables have a layer of insulation protection, they can reduce the risk of lightning on the line. Even if there is lightning, the impact will be much smaller, which can reduce the power outage time due to ground faults.

2.Suitable for reconstruction of old cities. Since the overhead insulated cable conductors can withstand a voltage of 15kV, the minimum vertical distance between the insulated cable and the building is 1m and the horizontal distance is 0.75m. Therefore, replacing low-voltage main lines with 10kY overhead insulated cables and sending them directly to the load center to shorten the power supply radius of the low-voltage power grid is an effective power distribution method for old city reconstruction.

Get A Free Quote

The number of cable cores is selected based on comprehensive consideration of multiple factors to ensure the rational use of the cable.

Copper core cables have excellent electrical conductivity, thermal conductivity and good mechanical strength.

Wires are an important part of circuit reconstruction. Household wires are mainly divided into copper wires and aluminum wires.

Submit Request

PDF Request