With the development of the electric power industry, high-voltage cables have been widely used in circuit transmission. In order to ensure the reliability and safety of power transmission, material selection and testing of high-voltage cables have become very important. The following blog post will describe what kind of insulation layer to choose for high-voltage power cables to meet the current impact brought by the voltage and how to detect it when receiving the goods?

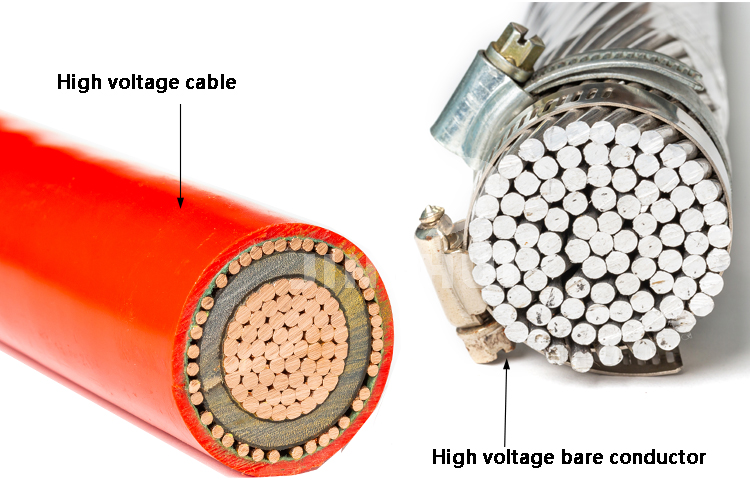

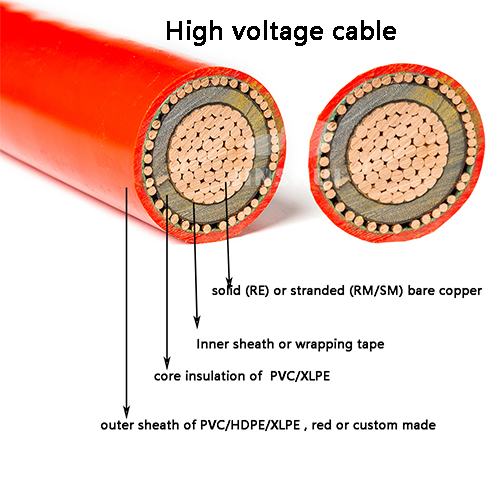

1.There is no need for an insulation protective layer for outdoor overhead cables. Buried cables do. The insulation material is a polyvinyl chloride insulation layer. The insulation cost of high-voltage cables is 10 times higher than that of ordinary overhead lines. For conductors of the same cross-section, the carrying capacity of cables is smaller than that of overhead lines. For the sake of appearance and safety, overhead lines are no longer visible in new urban areas, and high-voltage and low-voltage lines are buried underground.

2.Due to the high insulation requirements of the high-voltage line on the insulation layer, the construction process is complicated, and the cost is high. Generally, bare aluminum conductors are used, and the height of the overhead line is increased to prevent electric shock accidents. High-voltage and low-voltage are generally bare wires. Near the low-voltage overhead lines in the old urban areas, the buildings are dense, and the high-voltage cables generally have wires with insulating layers.

3.Due to the continuous improvement of power system systems, regulations and technologies, electric shock accidents have been greatly reduced. Generally, it is unlikely to be exposed to voltage levels above 10kV, and electric shock accidents at voltage levels above 10kV rarely occur. Therefore, there is no need to use insulated wires for such high-voltage lines.

Of course, there are also high-voltage lines covered with insulation, which we call high-voltage cables. High-voltage cables are generally used in areas that are not suitable for constructing overhead lines and are mostly laid underground. In addition to a thick insulating layer, high-voltage cables use copper cores as conductors. Therefore, the cost of high-voltage cables is more than 10 times that of ordinary overhead lines. Unless it is absolutely necessary, this method will not be used.

Electric shock caused by high voltage can be divided into two types: step voltage electric shock and high voltage arc electric shock.

1.Step voltage electric shock means that if the high-voltage transmission line falls on the ground, after the current flows into the ground, the potential near the ground point will gradually decrease to the distance, then there will be a voltage difference at the position where the two feet stand, and the current will flow The human body causes electric shock, which is a step voltage electric shock.

2.High-voltage arc electric shock is when people get close to high-voltage equipment to a certain distance, arc discharge will occur, that is, you will see a flash of light for a moment, and then the electric shocker will be knocked down by the high voltage and injured or even die.

The testing methods of high-voltage cables include appearance testing, electrical performance testing, mechanical performance testing and radiation testing.

Appearance inspection is one of the most basic high-voltage cable inspection methods, mainly through visual inspection or simple tools. The inspection content includes whether there is damage, scratches, deformation, etc. on the surface of the cable, and whether the connection of the cable end is firm. Appearance inspection is simple and easy, and some obvious defects or faults can be discovered in time.

(1) Impedance detection: Impedance detection is to check the impedance value between the cable insulation layer and the metal sheath to determine whether there is insulation deterioration or failure. By measuring the impedance values at different locations on the cable, the degree and location of cable degradation can be determined.

(2) Insulation test: Insulation test is an important means to check the insulation performance of cables. By applying a certain voltage, observe whether there is insulation breakdown or leakage in the cable. Qualified insulation performance is the key to ensuring the safe operation of high-voltage cables.

(1) Tensile test: The tensile test is to test the performance of high-voltage cables under a certain tensile force. By applying different levels of pulling force, observe the change of the cable to ensure that the cable can resist the influence of external mechanical stress during operation.

(2) Bending test: The bending test is to test the performance of high-voltage cables under different bending radii. Bend the cable into circular arcs with different radii, and observe whether the cable is cracked or falls off. To determine whether the cable can maintain stable performance under different bending states.

(3) Compression test: The compression test is to test the performance of the high-voltage cable under a certain compression force. By applying different levels of compressive force, observe the changes in the cable to determine how the cable will perform when subjected to external compressive stress.

The radiation test is to evaluate the electromagnetic radiation level generated by the high-voltage cable during operation. By measuring the radiation intensity of the cable at different frequencies, judge whether it meets the relevant standard limits, so as to ensure that the electromagnetic radiation of the cable to the surrounding environment during operation is within a safe range.

The wire and cable products produced by Zhengzhou Jinshui Cable Group are in strict accordance with international production requirements, and all products will be subject to strict quality inspection when they leave the warehouse. However, we still need to continue to strengthen the detection and maintenance of high-voltage cables to prevent potential failures and improve the stability of the power system.

Get A Free Quote

The number of cable cores is selected based on comprehensive consideration of multiple factors to ensure the rational use of the cable.

Copper core cables have excellent electrical conductivity, thermal conductivity and good mechanical strength.

Wires are an important part of circuit reconstruction. Household wires are mainly divided into copper wires and aluminum wires.

Submit Request

PDF Request