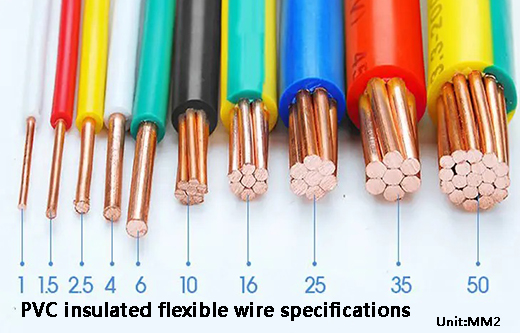

PVC insulated flexible wire is a commonly used wire material, consisting of copper core and polyethylene insulation material. It is suitable for power systems with a rated voltage of 0.6/1kv. It has excellent conductivity and electrical properties and can be used for power transmission and distribution. Polyethylene insulation material makes wires have high voltage resistance and corrosion resistance, and has certain high temperature resistance. It is widely used in construction, communications, industry and other fields, as well as household appliances, industrial equipment and automation control equipment. The following will elaborate on PVC insulated flexible wires and introduce similar types of wires.

1.Good insulation properties: PVC material has good electrical insulation properties and can effectively prevent current leakage and leakage. This allows PVC insulated flexible wires to maintain high safety during power transmission.

2.Soft and strong folding resistance: PVC insulated flexible wires have excellent flexibility and folding resistance, which can facilitate bending and folding operations during construction and wiring. Its flexibility allows the wires to be easily installed and maintained in complex wiring environments.

3.Strong corrosion resistance: PVC material has good chemical stability and corrosion resistance, and can resist the erosion of acids, alkalis, oils and some chemical substances, thereby ensuring the long-term service life of PVC insulated flexible wires.

4.Stable and reliable comprehensive performance: Through reasonable design and strict production technology, PVC insulated flexible wires have uniform insulation thickness, good wear resistance and mechanical strength, making the wires have stable and reliable performance during use.

1.XLPE insulated nylon sheathed wire(THHN THWN Copper Conductor): Compared with PVC insulated flexible wires, cross-linked polyethylene insulated wires have higher insulation heat resistance and aging resistance, and are suitable for power transmission in high temperature environments.

2.Polyurethane insulated wire: Polyurethane insulated wire has good high temperature resistance and tensile strength, and is suitable for high temperature environments or power transmission that needs to withstand greater tension.

3.PVC sheathed wire: PVC sheathed wire is a wire with a PVC sheath added outside the insulation layer. It is mainly used for outdoor fixed wiring and underground laying. It has good waterproof and UV resistance properties.

4.Low-smoke halogen-free flame-retardant wires: Low-smoke halogen-free flame-retardant wires are made of halogen-free materials. They have self-extinguishing properties, low smoke, and non-toxic characteristics. They reduce the generation of harmful gases and smoke when a fire occurs, and improve The safety of personnel escape.

Stirring: uneven mixing, the plasticizer wraps the PVC and produces particles;

Dead Angle: Refers to the fact that the barrel is not cleaned cleanly when mixing different batches of materials, and the remaining materials are excessively gelled.

Extrusion: The temperature is not enough, the gelation is poor, and particles are produced; a filter can be used to increase the back pressure to reflow the PVC that is not well gelled.

The impurities mainly come from CCR and CaCO3 in the raw materials; there are very few impurities from the stabilizer: less in the calcium-zinc system and more in the lead-based system.

(1) The extrusion temperature is too high and the cooling efficiency of the air cooling machine is low, resulting in agglomeration;

(2) The extrusion temperature is normal, and the occurrence of agglomeration is generally related to the stabilizer in the raw material. Clumping is related to operation and can be avoided by regulating temperature

(1) Human factors: color matching;

(2) It is related to the material; the stabilizer is very poor, and the PVC deteriorates and turns yellow due to constant stirring and heating during the color matching process.

Human operating reasons - the processing temperature is too high, insufficient external lubricant, and low molecular weight substances are vaporized; machine reasons - the air entrained in the material is squeezed out during the extrusion process, and poor machine exhaust will cause small pores.

It is related to the machine and operating temperature.

(1) Materials: CaCO3 particle size is unstable and too large (heavy calcium 2500 particle size is below 1.5um)

(2) Human operation: The proportion of lubricant is too low

To sum up, PVC insulated flexible wire, as a common wire material, has the characteristics of good insulation performance, softness, strong folding resistance and strong corrosion resistance, and is widely used in various fields. At the same time, products similar to PVC insulated flexible wires also include cross-linked polyethylene insulated wires, polyurethane insulated wires, PVC sheathed wires and low-smoke halogen-free flame-retardant wires, etc. Zhengzhou Jinshui Wire & Cable Group reminds everyone to choose the appropriate wire type according to actual needs.

Get A Free Quote

Flame-retardant cables are resistant to high temperatures and are not easy to burn, which can effectively prevent the spread of fire.

Jinshui Wire & Cable Group will participate in the Kenya Power and Energy Exhibition from June 26 to June 28, 2024.

Cables and overhead cables need to be selected according to their specific application scenarios.

Submit Request

PDF Request